Where did Airush’s journey with Ultra PE start?

We’ve been using Ultra PE in our Load Frame for over 10 years, so we had early insight into how it could improve material responsiveness and durability. Our first real project was with Dyneema Corporation about eight years ago. That’s when we saw both the huge potential and the challenges – it looked like the perfect solution on paper, but we knew it would be a long road.

From there, we partnered with ALUULA, Challenge Sailcloth, and Dimension Polyant. What’s important for us is a closed-loop process – our designers define the characteristics we need, then we work hand-in-hand with the fabric partner to refine it through long-term testing and mass production.

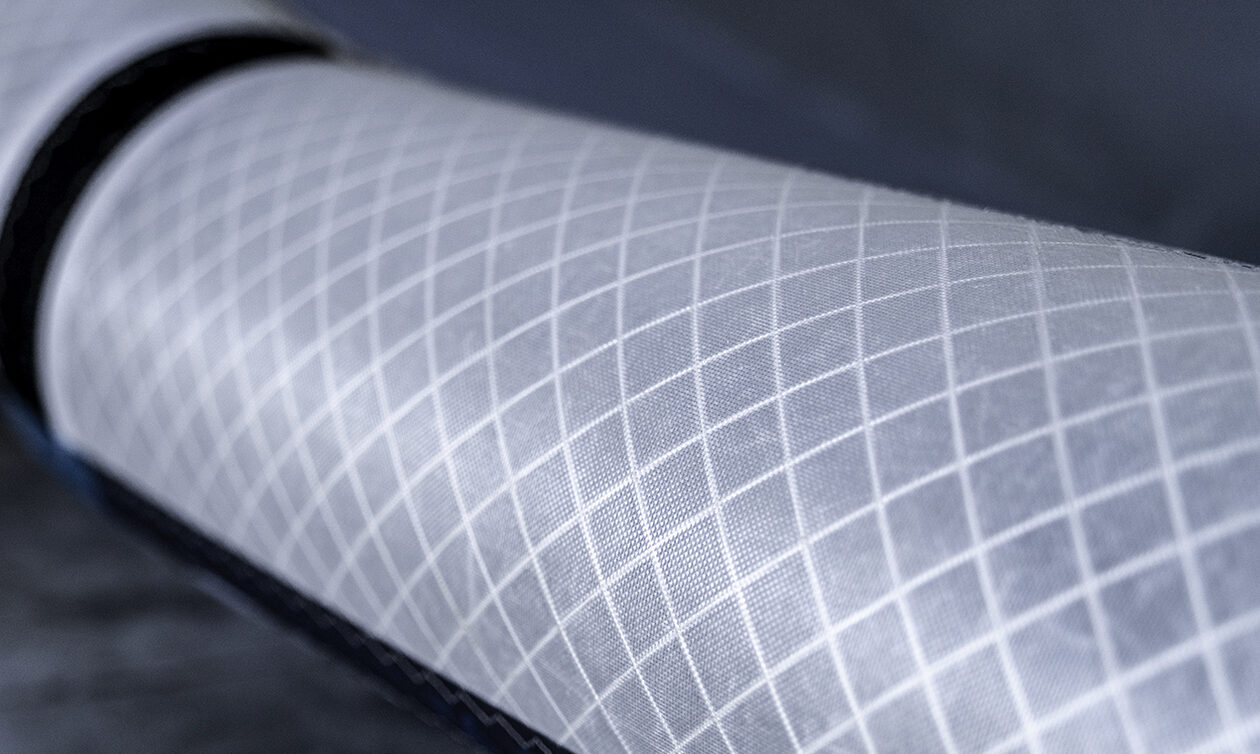

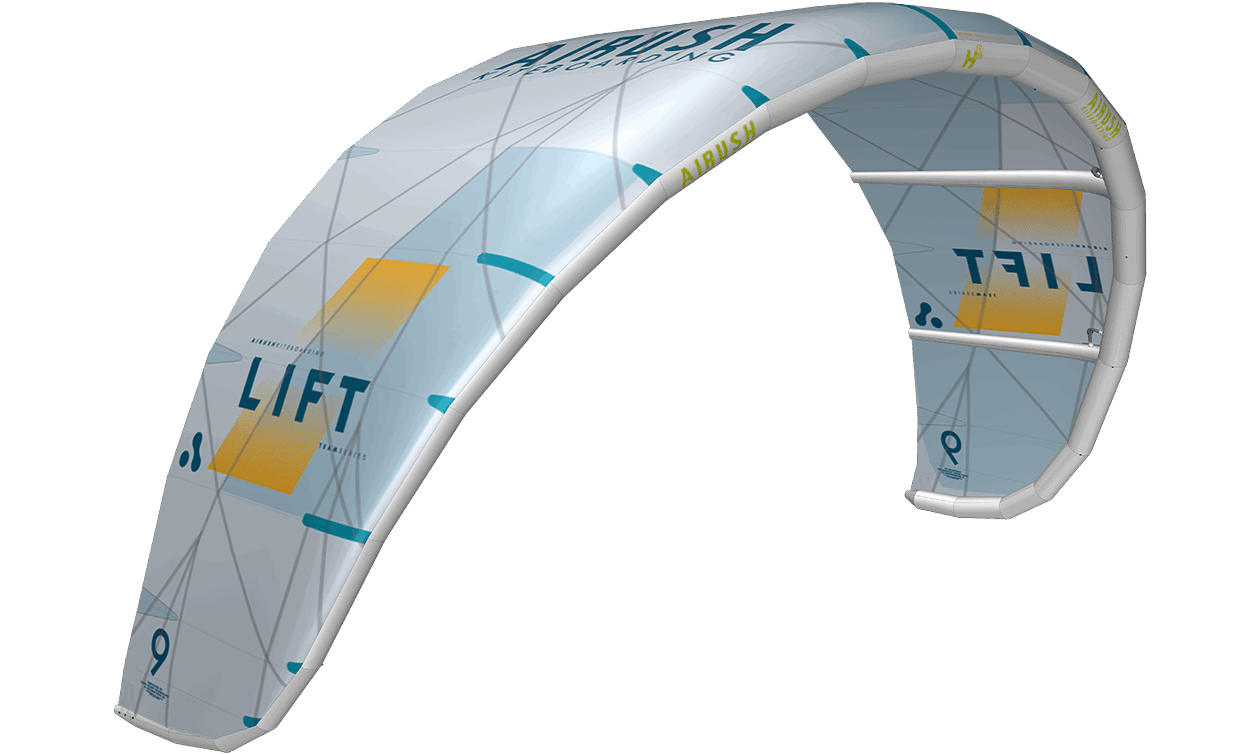

Ho’okipa worked well for us because of its bias properties, which matched what we wanted in terms of higher pressures and durability. ALUULA Aeris then gave us incredible weight savings through a new bonding process. With H2, we’ve come full circle – back to a primarily woven Ultra PE – but with some major refinements.

So how does H2 compare to Ho’okipa?

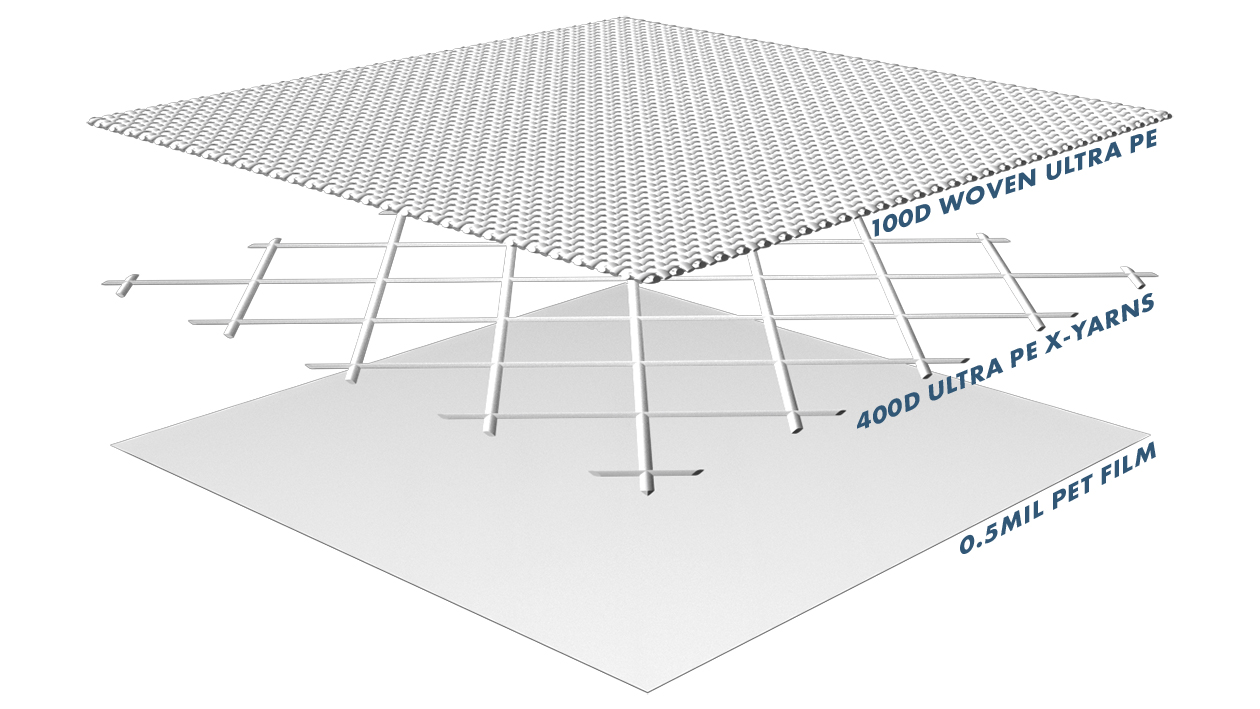

Weight is the first big difference. H2 comes in under 85gsm. Ho’okipa is about 120gsm, and regular Dacron is around 160gsm. So both are lighter and more responsive than Dacron, but H2 pushes things further.

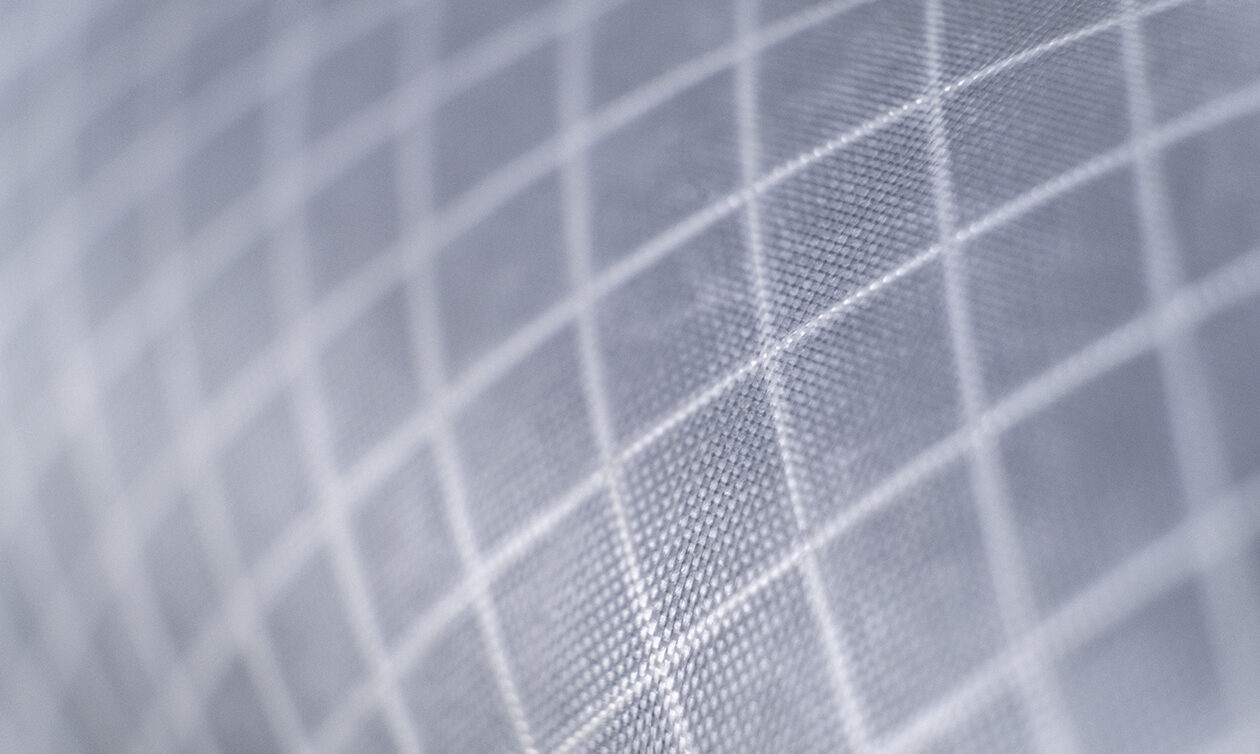

The construction is also different. H2 is 100D 100% Ultra PE, whereas Ho’okipa is a 200D blend of 50% Ultra PE and 50% polyester. The manufacturing process has also taken a big step forward – tighter, more stable weave, higher pre-tension stability, less bias stretch, and lower weight after lamination.

On the water, the key thing riders will notice is elongation – or really, the lack of it. H2 shows the lowest stretch in our lab tests, which means the kite keeps its shape under inflation, responds instantly to bar input, and snaps back straight when you let go of the steering.